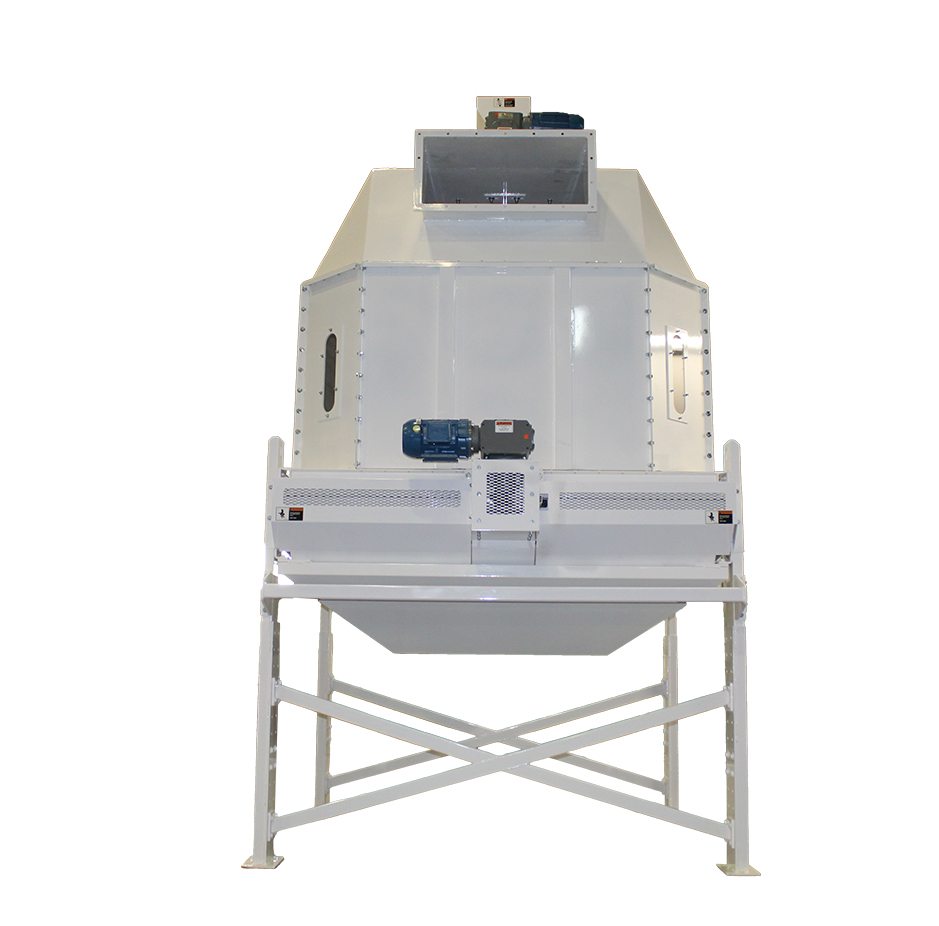

MILL- C12 Pellet Cooler

SKU # MILL-C12

Call for Pricing

The MILL-C12 Pellet Cooler: Cooling Excellence from 6 to 12 Tons per Hour

The MILL-C12 Pellet Cooler offers effective cooling for pellets with capacities ranging from 6 to 12 tons per hour. Its performance is determined by pellet size, density, temperature, and composition.

The unit includes a 1900 x 1900 mm grid with a dwell time of approximately 10 – 15 minutes. Unit shown features the optional top-installed rotary airlock and discharge bin.

* Options shown in images and/or videos are sold separately and not included in price.

Max Capacity

107 Cubic Ft

Air System Blower

CFM 4900 CFM at 12” static pressure

Cooler Weight

4815 LBS (including top airlock valve)

Cyclone

Weight

900 LBS

Cooler Infeed Height

166.6″ MN – 202.5″ MAX

Cooler Discharge Height

17.6″ – 53.6″

Cyclone Airlock Discharge

37.16″

- Variable swing discharge grid

- Heavy-duty construction

- Easy maintenance

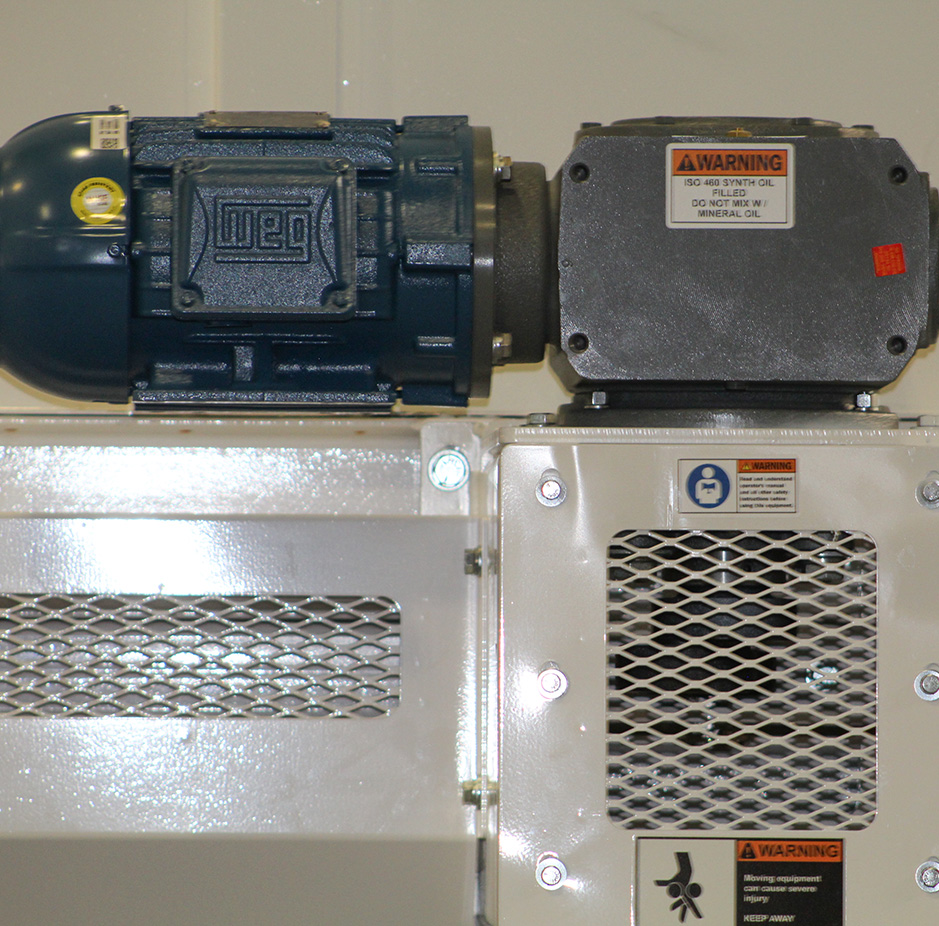

- Equipped with a 2 HP motor

- Heavy-duty Cleveland gearbox

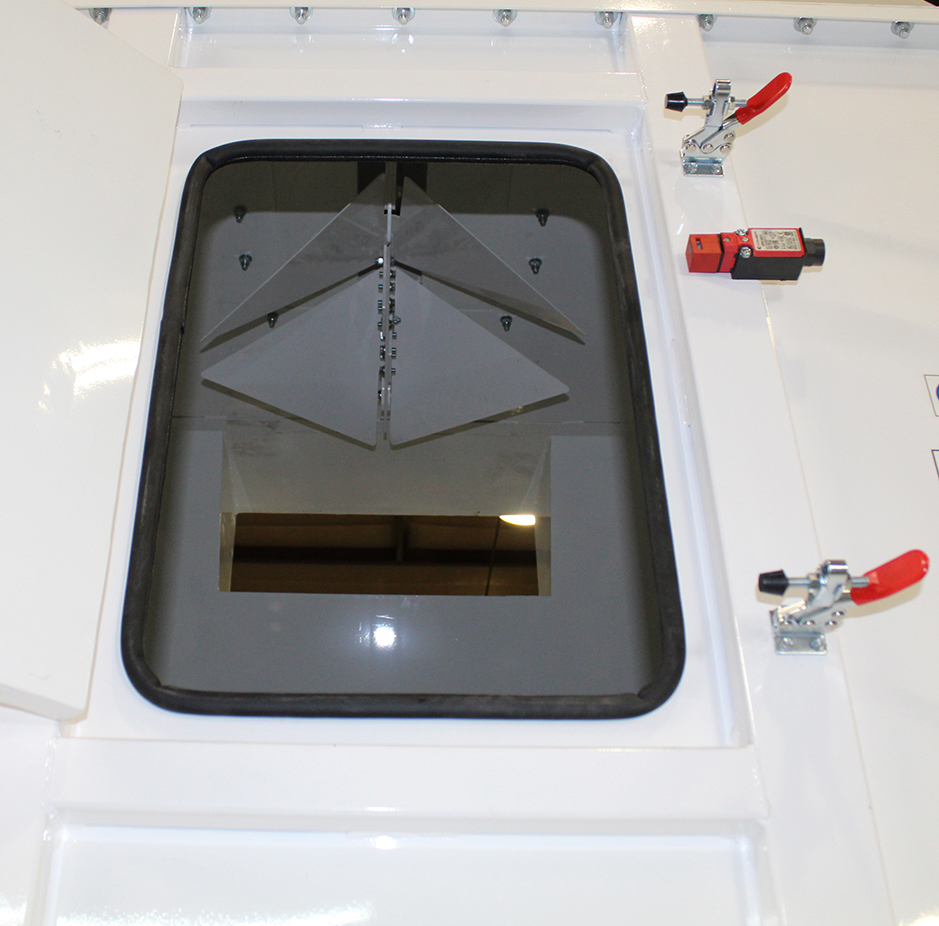

- Ultra diffusion spreader with 4-way adjustment

- Triple grid system for minimal product breakage

- Ultra compact footprint

- Powder coated with FDA-approved materials

- Manway Door

- Safety interlock

- Designed, built, & supported in the USA

- CME’s Signature 1-Year Manufacturer’s Warranty

- Required component (select one): Discharge Bin for use with Screener or Gravity Discharge Bin

- SCR46 Screener

- Top Airlock

- Cyclone Airlock

- Air System (Blower Stand, Cyclone, Ductwork)

- Safety Control Panel

- Cubing Grid

- Alfalfa

- Corn

- General Feed

- Hemp/Cannabis

- Oats

- Poultry Litter

- Soybean Meal

- Wheat

- Fertilizer

- Carbon

- Wood

- Wood Grill Pellets

- Plastics

- Fertilizer

- Hemp/Cannabis

- Hops

- Animal Feed

- Ethanol

- Wood Processing

- Recycling & Plastics

- Soybeans

CME Is Your Best Choice

Colorado Mill Equipment is an innovative company dedicated to providing high quality pelletizing, milling, and bagging equipment to meet the needs of a global industry. We are equipped to run tests on a wide variety of products, refurbish equipment, supply spare parts, and ship machinery internationally.

We offer a “test your material before you buy” option

All parts are in stock in the USA, at our own facility

In-house training included with every pellet mill purchase

Lifetime technical, application, and engineering support

Recommended Products

Assembled in the USA

Our equipment is engineered and supported in the USA