Equipment

American-Made Machinery, Ready When You Are

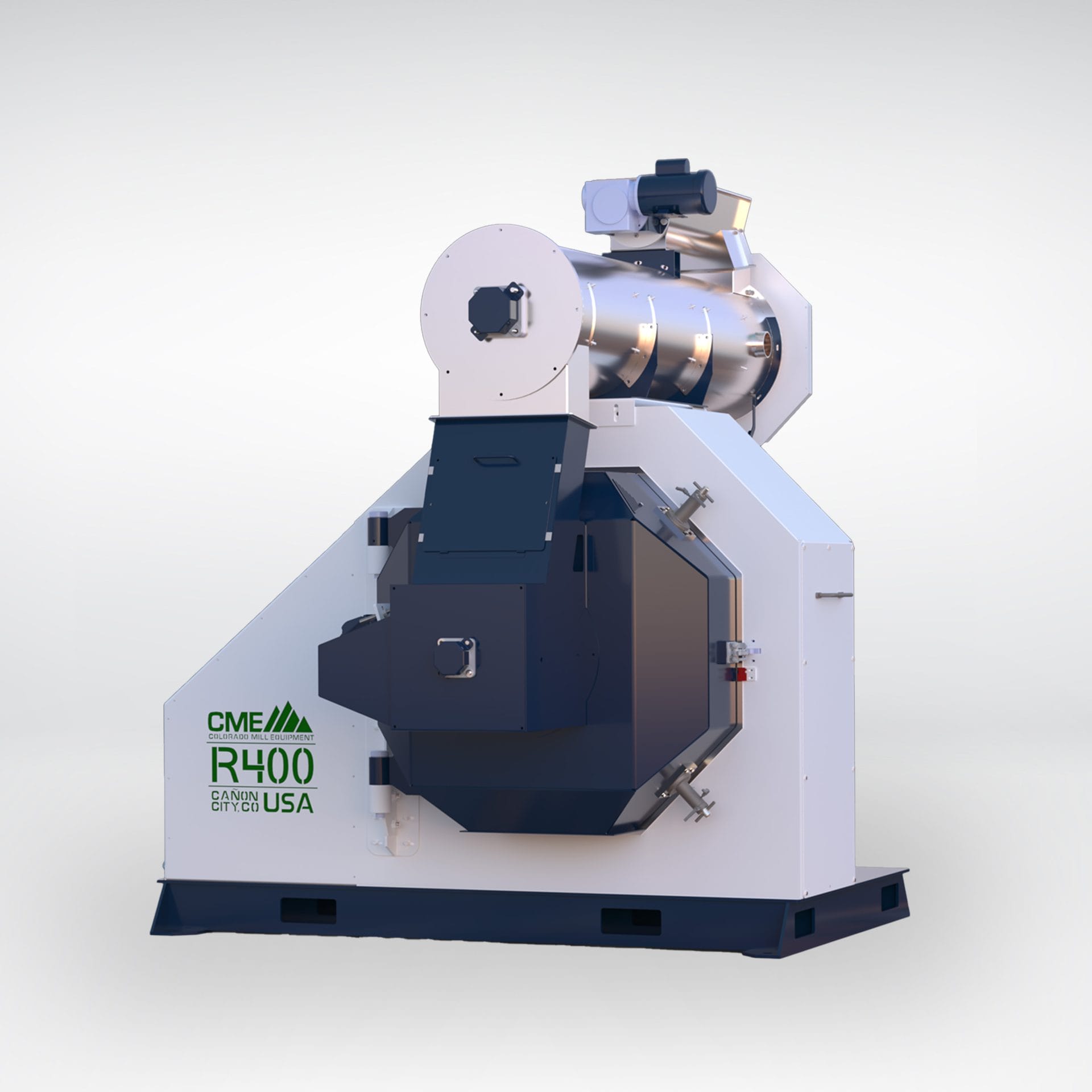

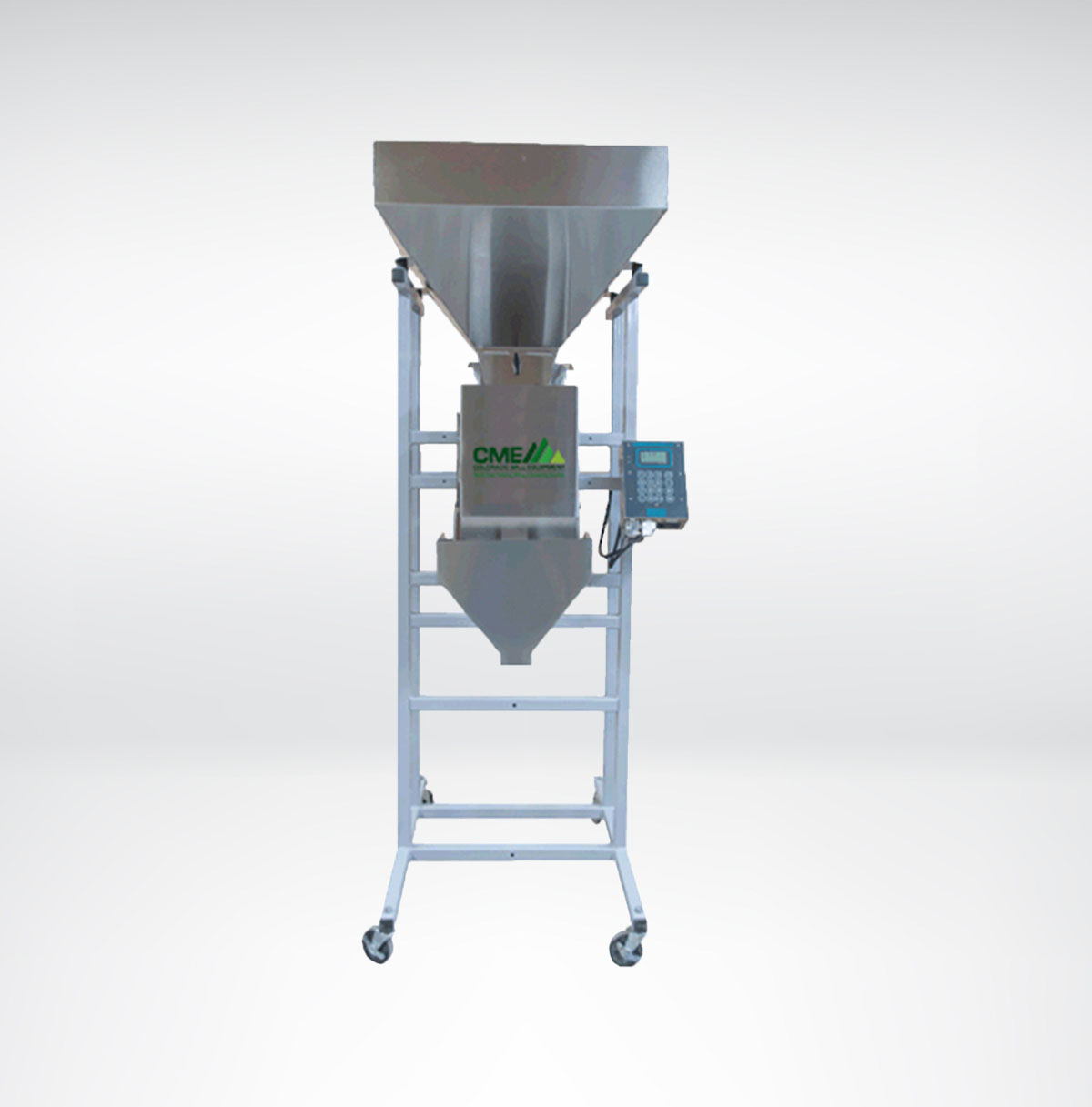

Our extensive product lineup includes Pellet Mills, Hammer Mills, Blenders/Mixers, Pellet Coolers, Crumblers, Screeners/Sifters, Bucket Elevators, and a top-of-the-line Bagging System. Every piece of equipment is designed, engineered, and built in-house at our facility in Canon City, Colorado — giving us full control over quality and craftsmanship.

We don’t just manufacture industrial machinery — we keep our most popular equipment in stock and ready to ship, so you can minimize downtime and start producing faster.

At CME, we’re more than a supplier. We’re your partner in building reliable, high-performance systems tailored to your exact needs. Get in touch today to see how our American-made equipment can power your operation forward.

Crumblers

Screeners / Sifters